Engineering

Machining

Carpentry

Assembly

Test Control System

Officine Meccaniche Pellanda stands out for its highly specialized and modern testing department, equipped with cutting-edge technology designed to guarantee the utmost quality and reliability of every manufactured component. Our commitment to precision engineering is supported by a suite of advanced measuring instruments, enabling us to validate complex geometries, ensure compliance with customer specifications, and maintain excellence across all production cycles.

To achieve this, we rely on portable coordinate measuring machines (CMM) such as the CAM2 Arm and the CAM2 Vantage Laser Tracker by FARO. These state-of-the-art tools enable 3D inspections, high-accuracy comparisons with CAD models, detailed dimensional analyses, and reverse engineering processes. This ensures that every product undergoes stringent and meticulous quality control, minimizing tolerances and preventing defects long before final assembly.

Among the most advanced solutions available on the market, the CAM2 Edge and the CAM2 Vantage Laser Tracker are central to our measurement operations. Renowned for their extreme accuracy and repeatability, they allow our engineers to perform real-time checks, validate complex assemblies, and meet the highest industry standards, thereby reducing downtime and avoiding costly rework.

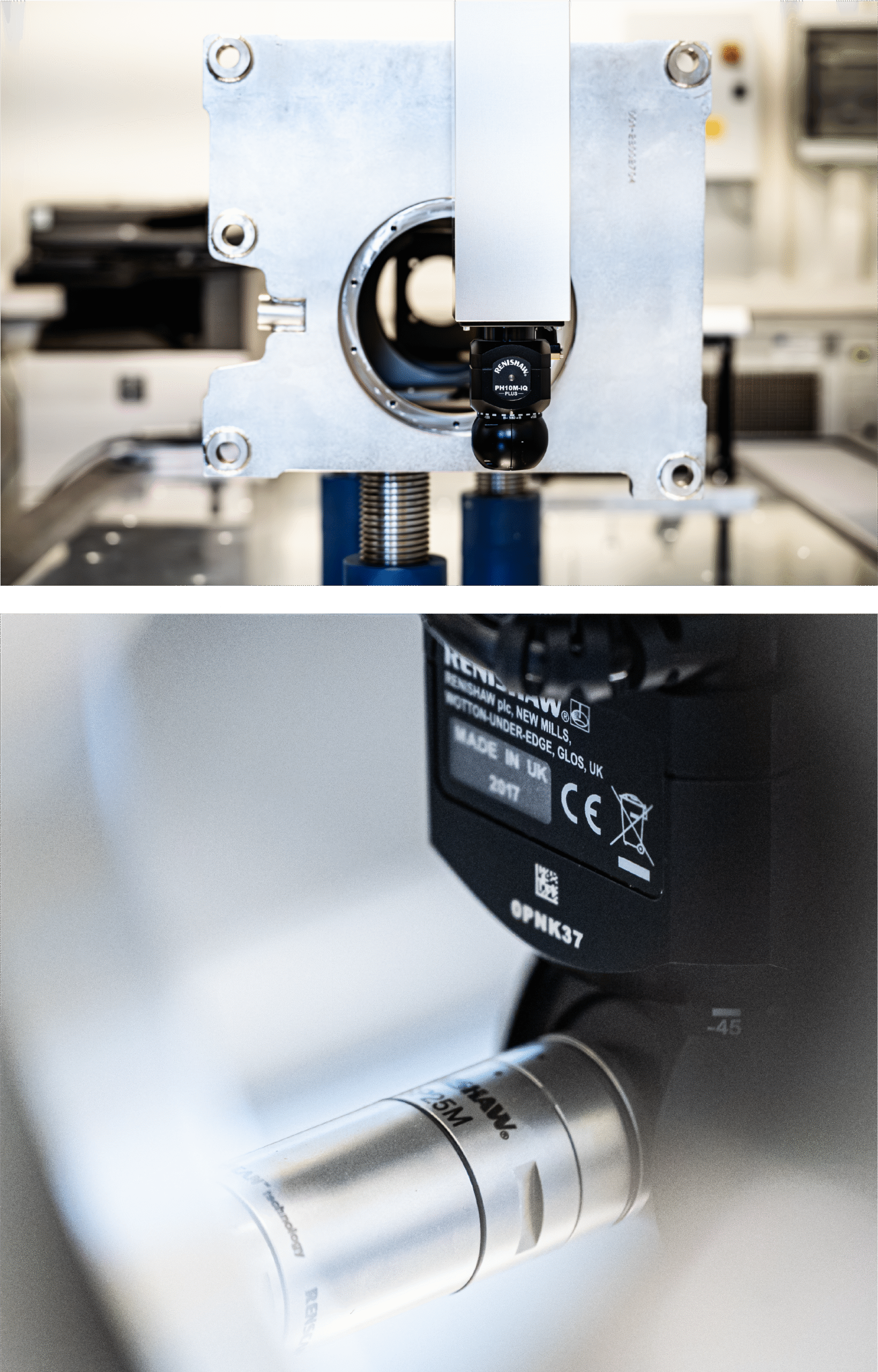

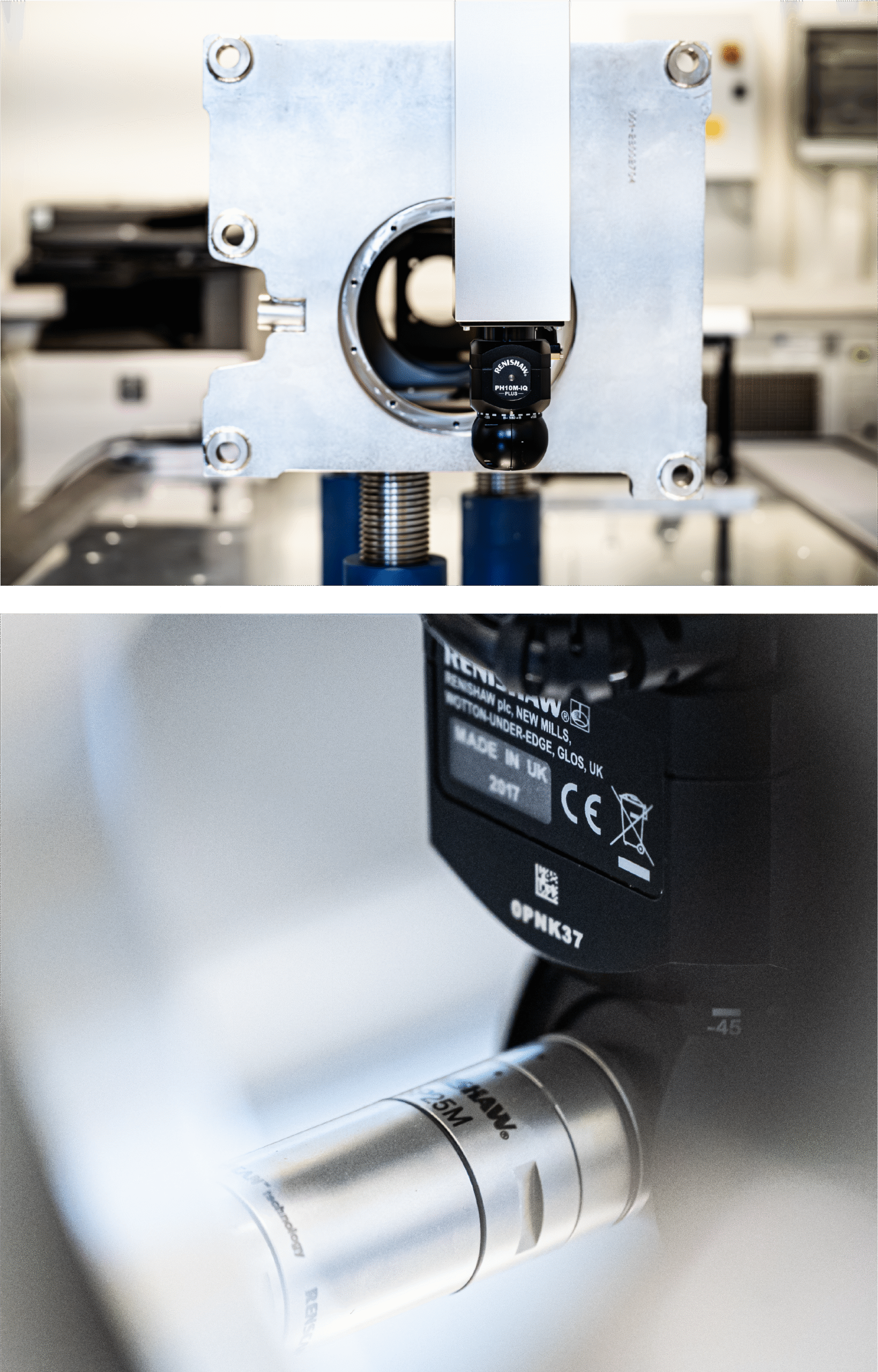

Our commitment to uncompromising quality extends further into our temperature-controlled testing room, where we house a CMM Global Advantage machine with dimensions of 1,200 mm x 3,000 mm x 1,000 mm. Equipped with Renishaw probes and the PC-DMIS CAD++ software suite, a global leader in coordinate measurement technology, this system ensures unparalleled measurement precision, reliability, and consistency, even on large-scale components. By monitoring and maintaining stable environmental conditions, we can guarantee repeatable results unaffected by external variables.

Have a Project in mind?

Get a free consultation with us today.

Officine Meccaniche Pellanda stands out for its highly specialized and modern testing department, equipped with cutting-edge technology designed to guarantee the utmost quality and reliability of every manufactured component. Our commitment to precision engineering is supported by a suite of advanced measuring instruments, enabling us to validate complex geometries, ensure compliance with customer specifications, and maintain excellence across all production cycles.

To achieve this, we rely on portable coordinate measuring machines (CMM) such as the CAM2 Arm and the CAM2 Vantage Laser Tracker by FARO. These state-of-the-art tools enable 3D inspections, high-accuracy comparisons with CAD models, detailed dimensional analyses, and reverse engineering processes. This ensures that every product undergoes stringent and meticulous quality control, minimizing tolerances and preventing defects long before final assembly.

Among the most advanced solutions available on the market, the CAM2 Edge and the CAM2 Vantage Laser Tracker are central to our measurement operations. Renowned for their extreme accuracy and repeatability, they allow our engineers to perform real-time checks, validate complex assemblies, and meet the highest industry standards, thereby reducing downtime and avoiding costly rework.

Our commitment to uncompromising quality extends further into our temperature-controlled testing room, where we house a CMM Global Advantage machine with dimensions of 1,200 mm x 3,000 mm x 1,000 mm. Equipped with Renishaw probes and the PC-DMIS CAD++ software suite, a global leader in coordinate measurement technology, this system ensures unparalleled measurement precision, reliability, and consistency, even on large-scale components. By monitoring and maintaining stable environmental conditions, we can guarantee repeatable results unaffected by external variables.

Have a Project in mind?

Get a free consultation with us today.