Engineering

Machining

Carpentry

Assembly

Test Control System

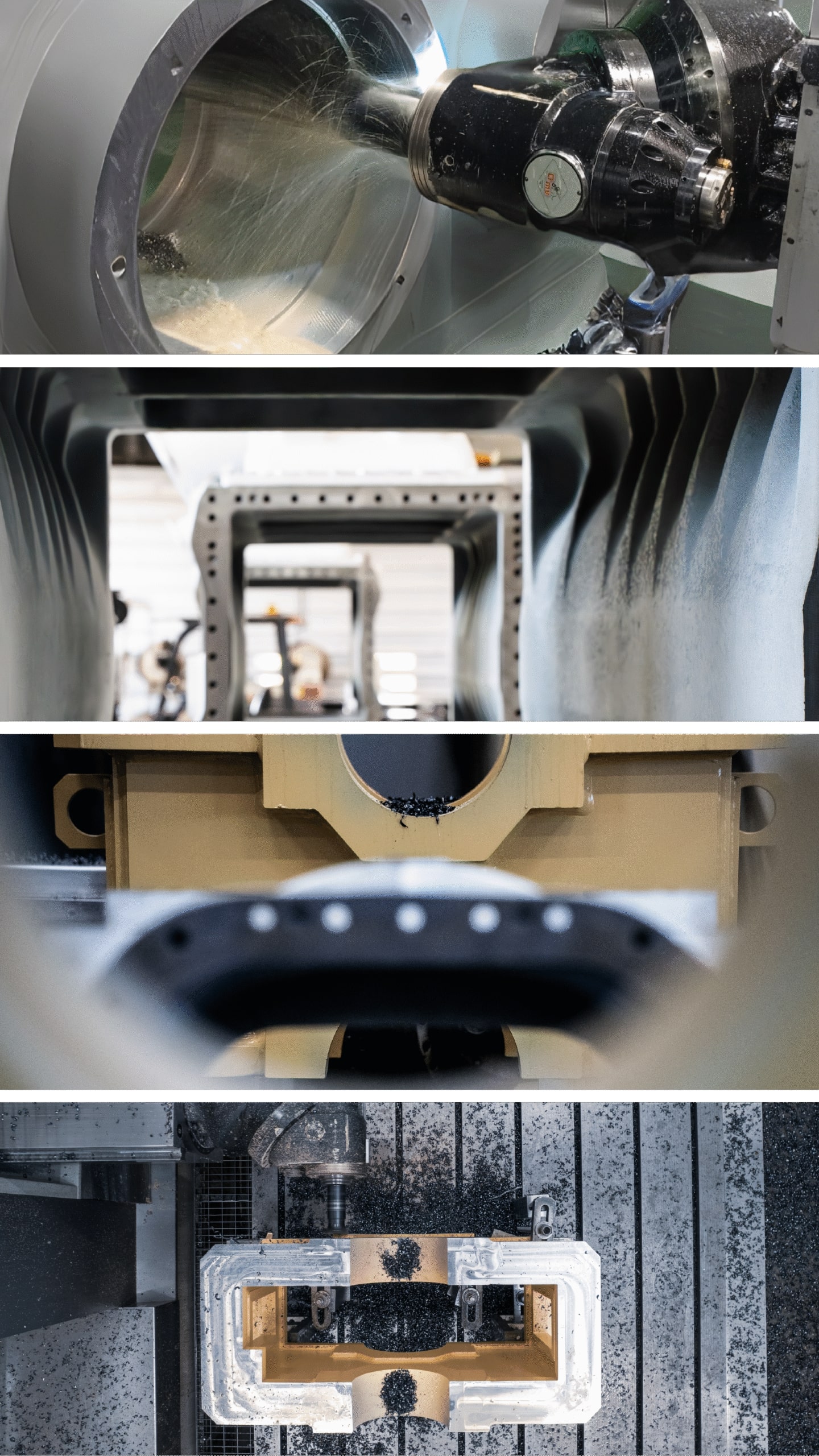

Officine Meccaniche Pellanda features a state-of-the-art machine park, specifically designed to satisfy the most advanced requirements in precision mechanical processing. The company’s CNC fleet includes cutting-edge machines capable of producing highly precise and customizable components, even for the most complex applications.

Each machine is carefully selected to integrate seamlessly with production workflows, ensuring optimal efficiency and outstanding results in every phase of work. An advanced information system supports the entire operation, allowing for precise programming, scheduling, and real-time monitoring of the production process.

The main equipment includes:

- 6-axis CNC milling machines O.M.V. PARPAS, each with impressive dimensions (8000x3125x1400 mm) and rotary tables of different sizes (2500×2000 mm) for handling large and complex workpieces, featuring a translation axis of 1,500 mm and a head with 0.001° precision.

- 6-axis CNC milling machines O.M.V. PARPAS, each with impressive dimensions (8000x3125x1400 mm) and rotary tables of different sizes (2000×2000 mm) for handling large and complex workpieces, featuring a translation axis of 1,500 mm and a head with 0.001° precision.

- 5-axis CNC milling machine FPT (3800x1100x1700 mm) designed for intricate multi-dimensional operations.

- MAZAK VTC 800/30 SR CNC milling machine (3000x800x720 mm) equipped with a rotary table (500×500 mm) and high-precision head (0.001°).

- MAZAK HCN-8800 ISO 50 CNC horizontal milling machine featuring the Palletech-Mazak system and a 12-pallet changer, enabling flexible and efficient batch processing; specifications include X, Y, and Z strokes of 1400 mm, 1200 mm, and 1325 mm, respectively, with a pallet size of 1000×1000 mm and capacity for workpieces up to Ø 1450 mm, delivering maximum torque of 1218 Nm.

This combination of highly specialized machinery and intelligent process management ensures Pellanda Officine Meccaniche can respond swiftly and effectively to the evolving needs of its clients, delivering top-quality, tailor-made solutions in the field of mechanical engineering.

Have a Project in mind?

Get a free consultation with us today.

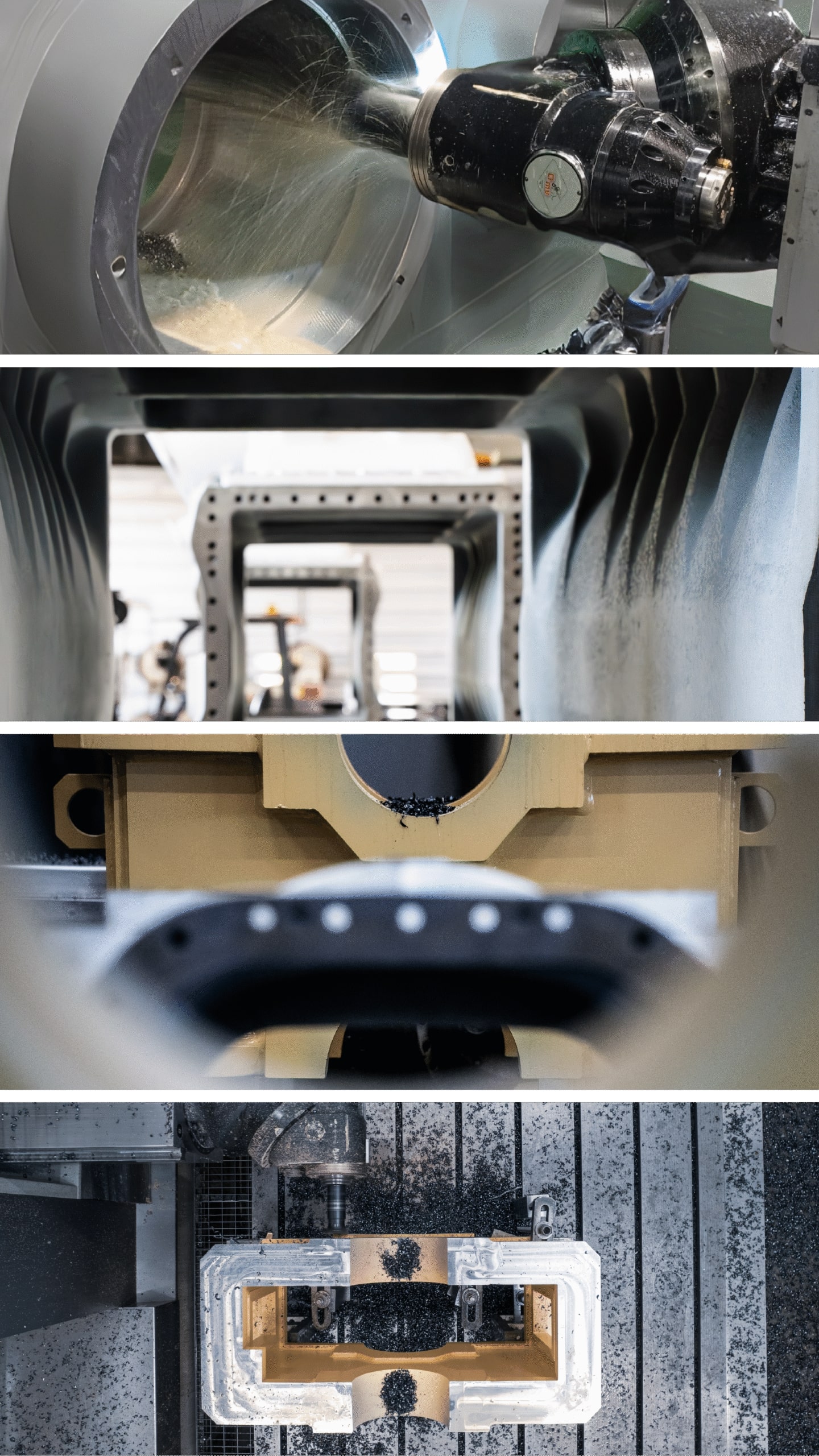

Officine Meccaniche Pellanda features a state-of-the-art machine park, specifically designed to satisfy the most advanced requirements in precision mechanical processing. The company’s CNC fleet includes cutting-edge machines capable of producing highly precise and customizable components, even for the most complex applications.

Each machine is carefully selected to integrate seamlessly with production workflows, ensuring optimal efficiency and outstanding results in every phase of work. An advanced information system supports the entire operation, allowing for precise programming, scheduling, and real-time monitoring of the production process.

The main equipment includes:

- 6-axis CNC milling machines O.M.V. PARPAS, each with impressive dimensions (8000x3125x1400 mm) and rotary tables of different sizes (2500×2000 mm and 2000×2000 mm) for handling large and complex workpieces, featuring a translation axis of 1,500 mm and a head with 0.001° precision.

- 5-axis CNC milling machine FPT (3800x1100x1700 mm) designed for intricate multi-dimensional operations.

- MAZAK VTC 800/30 SR CNC milling machine (3000x800x720 mm) equipped with a rotary table (500×500 mm) and high-precision head (0.001°).

- MAZAK HCN-8800 ISO 50 CNC horizontal milling machine featuring the Palletech-Mazak system and a 6-pallet changer, enabling flexible and efficient batch processing; specifications include X, Y, and Z strokes of 1400 mm, 1200 mm, and 1325 mm, respectively, with a pallet size of 1000×1000 mm and capacity for workpieces up to Ø 1450 mm, delivering maximum torque of 1218 Nm.

This combination of highly specialized machinery and intelligent process management ensures Pellanda Officine Meccaniche can respond swiftly and effectively to the evolving needs of its clients, delivering top-quality, tailor-made solutions in the field of mechanical engineering.

Have a Project in mind?

Get a free consultation with us today.