Engineering

Machining

Carpentry

Assembly

Test Control System

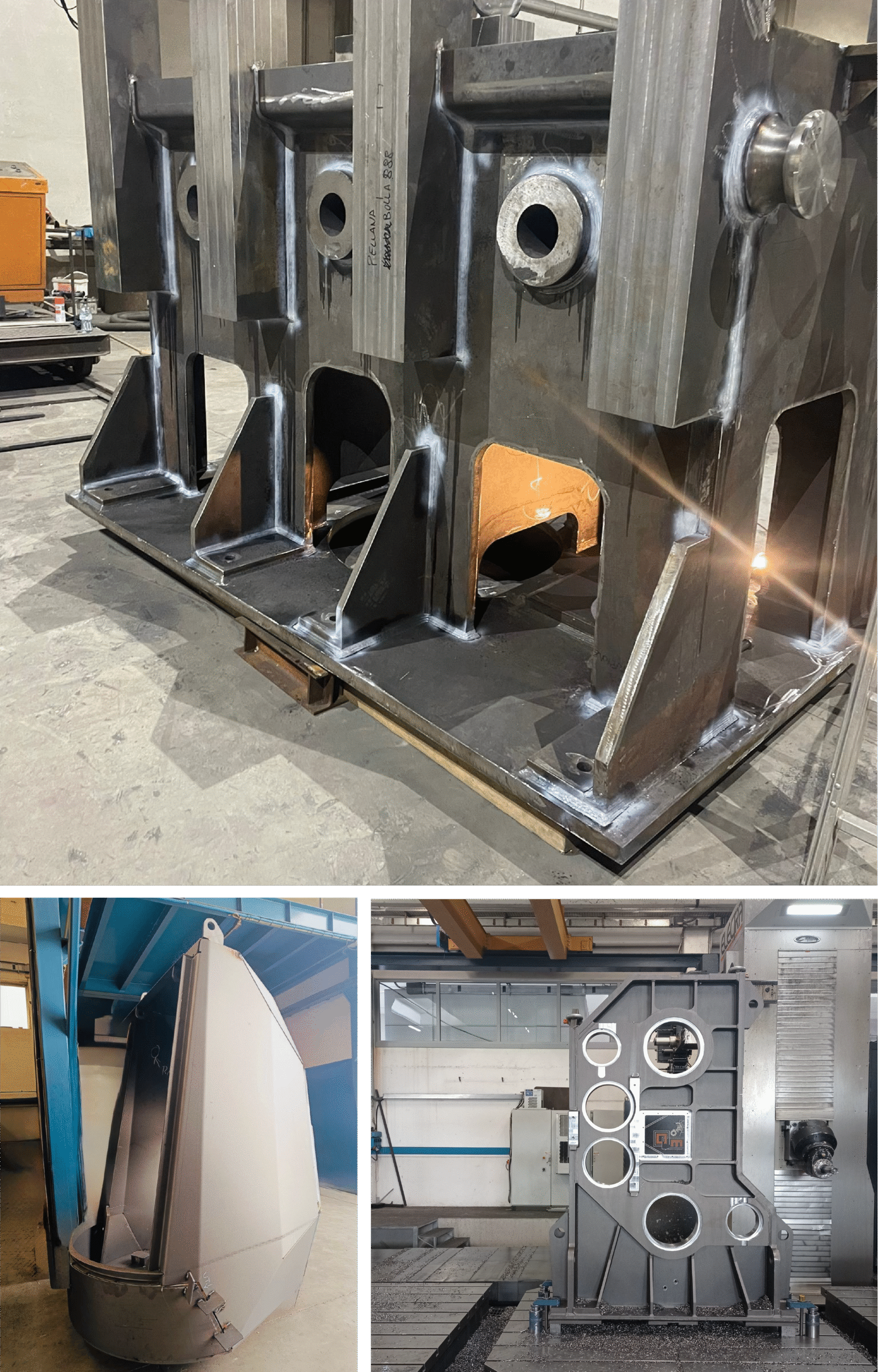

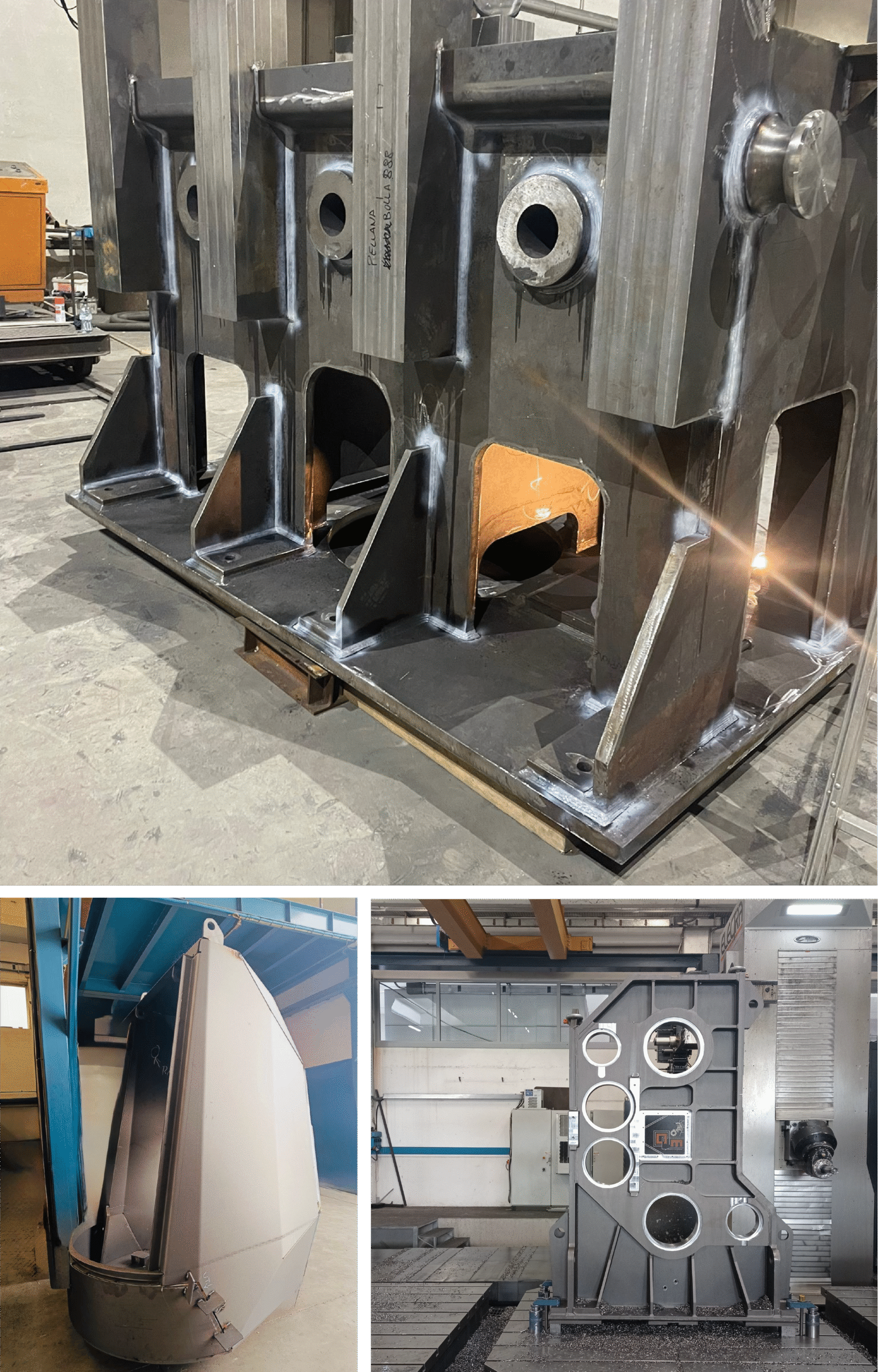

Officine Meccaniche Pellanda excels in welding complex industrial components, seamlessly integrating with precision machining. We invest continuously in quality, backed by certifications including UNI EN ISO 3834-2, UNI EN 1090 EXC 3, UNI EN 15085-2, and AWS D1.1 Structural Welding – Steel for the U.S. market.

Our expertise enables design and production of large welded components, up to 8m long, 3m wide, and 10 tons, ensuring structural robustness for demanding sectors like railways, energy, and industrial construction. We incorporate IPG LightWELD Laser Welding and cleaning systems, which deliver fast, easy-to-learn, high-quality welds on diverse materials and thicknesses, with pre- and post-weld cleaning to optimize quality and productivity.

Throughout production, we conduct non-destructive testing, pressure tests, and calibrated measurements, overseen by certified welding coordinators, guaranteeing precision, durability, and safety. This synergy of expertise, certified processes, rigorous controls, and innovative technology positions us as an excellence partner for national and international clients in certified industrial welding.

Have a Project in mind?

Get a free consultation with us today.

Officine Meccaniche Pellanda stands out for its specialization in welding complex industrial components, offering a service that perfectly integrates with precision machining operations. Our company continuously invests in quality and excellence, as demonstrated by certifications such as UNI EN ISO 3834-2, UNI EN 1090 EXC 3, UNI EN 15085-2, and AWS D1.1 Structural Welding – Steel for the U.S. market.

Thanks to our expertise, we are capable of designing and manufacturing large welded components – up to 8 meters in length, 3 meters in width, and weighing up to 10 tons – guaranteeing structural robustness and reliable performance even in the most demanding applications. Our services cater to high-intensity sectors such as railways, energy, and industrial construction.

At every stage of the production cycle, we perform non-destructive testing and pressure tests to verify the quality, strength, and durability of the welds, ensuring maximum safety for our clients and their facilities. We use advanced measuring equipment, constantly calibrated, to meet the dimensional parameters and standards required by each specific order.

The entire process is overseen by highly qualified personnel, including certified welding coordinators, making every operation synonymous with precision and long-term durability.

The synergy between technical expertise, certified process management, and rigorous quality controls enables Officine Meccaniche Pellanda to meet the needs of both national and international clients and to position itself as a partner of excellence in the field of certified industrial welding.

Have a Project in mind?

Get a free consultation with us today.